Posted on

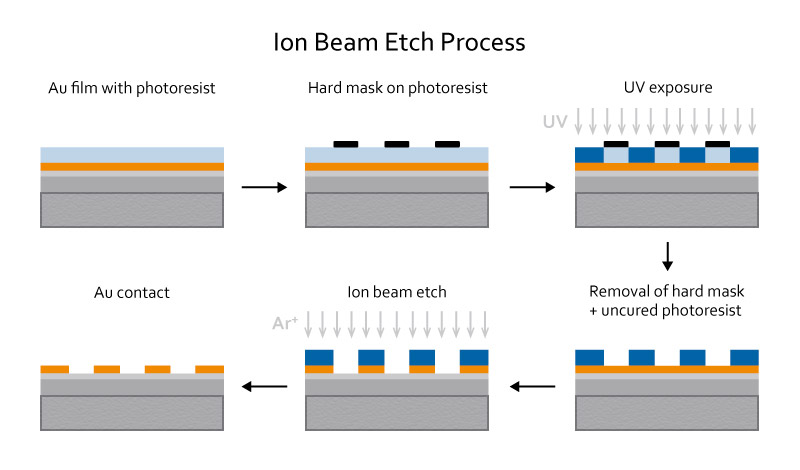

Ion beam etching (IBE) is a thin film technique that utilizes an ion source to carry out material removal processes on a substrate. IBE is a type of ion beam sputtering and, whether it’s used for pre-clean or patterned etching, it helps ensure excellent adhesion and precise formation of 3D structures.

Benefits of Ion Beam Etch

Ion beam etching offers:

- Excellent process control: IBE delivers tight process control for etching patterns onto a substrate. For applications that require precise specs for material removal, IBE can create highly uniform, specific patterns using masking.

- Precision for multilayer stacks: IBE is a highly repeatable solution for etching stacks of multiple materials or layers. With a configuration that integrates SIMS (secondary ion mass spectroscopy) as an in-situ control, ion beam etch allows you to remove layers of one material and stop immediately at the next layer.

- Thorough substrate preparation: Ion beam etch features high-energy ions for a high-impact plasma treatment. It is one of the most thorough pre-clean methods available, capable of removing every particle or even entire layers from the substrate before sputtering. This can be useful when removing a native oxide layer, for example, but care must be taken not to damage underlying devices.

- High uptime: When angling or substrate rotation is used, it enables the creation of processes that result in tailored sidewall profiles with minimal sputtered redeposition on overlying masks, minimizing maintenance requirements.

Ion Beam Etch Configurations

In an ion beam etch system, a broad beam collimated and highly directional ion source is used to physically mill material from a substrate mounted on a rotating fixture with adjustable tilt angle. Typically, gridded ion sources are used and are neutralized with an independent electron source.

There are also two other types of ion beam etching: reactive ion beam etching (RIBE) and chemically assisted ion beam etching (CAIBE).

RIBE is identical to IBE, except that some or all of the ion beam is composed of reactive ions; in standard IBE, the ion beam is composed of only inert gases. In CAIBE, un-ionized reactive species are introduced into the process independent of the ion beam, close to the substrate. For certain materials, RIBE and CAIBE offer additional control of etch anisotropy, sputter redeposition and etch rate over IBE.

To explore other pre-treatment methods and configurations, read our technical paper, Pre-Cleaning in Thin Film Physical Vapor Deposition. Learn more about Denton’s solutions for ion beam etch and ion beam deposition here.