Infinity FA System

The Infinity FA System is a high-performance etching tool designed for failure analysis sample preparation, critical thin film profiling and delayering in semiconductor manufacturing.

View DetailsIon Beam Sputtering (IBS), also called Ion Beam Deposition (IBD), is a thin film deposition process that uses an ion source to deposit or sputter a target material (metal or dielectric) onto a substrate to create either a metallic or dielectric film. Because the ion beam is monoenergetic (ions possess the equal energy) and highly collimated, it enables extremely precise thickness control and deposition of very dense, high quality films as compared to other PVD (physical vapor deposition) technologies.

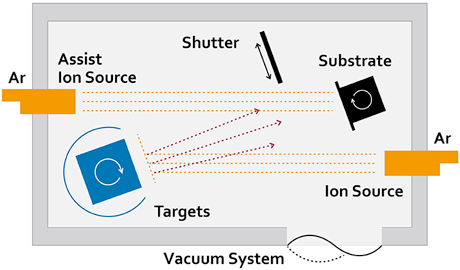

The typical configuration of an IBD system is a gridded ion source, a target, and the substrate. The ion beam is focused on a target material, and the sputtered target material deposits onto a nearby substrate. It is common practice to utilize a second gridded ion source directed at the substrate to provide for ion assisted deposition (IAD). IAD is particularly useful when depositing metal oxide or nitride films to improve the film’s physical density, moisture stability, optical, and mechanical properties. In addition, it may be desirable to heat the substrates during deposition to improve overall performance.

A key advantage of IBD is independent control of several parameters, including target sputtering rate and IAD parameters – ion energy, ion current density, and angle of incidence for control of film stoichiometry and microstructure. This level of control is the main difference between ion beam and other sputtering processes, making IBD a great choice for the most challenging applications such as precision optics or semiconductor production.

Denton Vacuum has developed solutions for ion beam sputtering that provide stable deposition rates for excellent film thickness and uniformity control. For details and specifications, take a look at our IBD solutions below.

Ion beam etch (IBE) is an IBD process that can be used to pre-clean a substrate, or to create a specific pattern on the substrate’s surface using masking. Similar to other pre-clean methods, IBE completely removes particles from the substrate before deposition; it can also be used to remove a layer from the substrate surface itself to ensure excellent coating uniformity and adhesion.

IBE is an excellent option for materials and applications that require precise specs for material removal. It offers tight process control and repeatability for etching patterns onto a substrate, particularly for etching stacks of multiple materials or layers. As a pre-cleaning method, IBE features high-energy ions for a high-impact plasma treatment. By leveraging Denton Vacuum’s portfolio of Infinity ion beam products, you can achieve excellent uniformity and repeatability in a system that is fully equipped for high-volume production.

The Infinity FA System is a high-performance etching tool designed for failure analysis sample preparation, critical thin film profiling and delayering in semiconductor manufacturing.

View Details

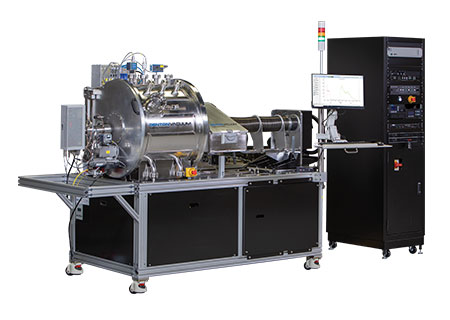

The Infinity IBD System delivers dense, defect-free films with extremely high precision and thickness uniformity. It offers independent control over ion energies, so you can achieve exacting thin film specs with very low contamination from flaking.

View Details

The Infinity PSIBE and the Infinity LL Etch systems are both class 1000 cleanroom compatible (ballroom style), ESD compliant and chemical assist is available for etch.

View Details

When you need a high-quality film for R&D in emerging applications, from optical interference coatings to x-ray mirror optics, the Infinity RM System is the solution for you.

Infinity RM