Posted on

What is plasma and why is it important in enabling thin film innovation?

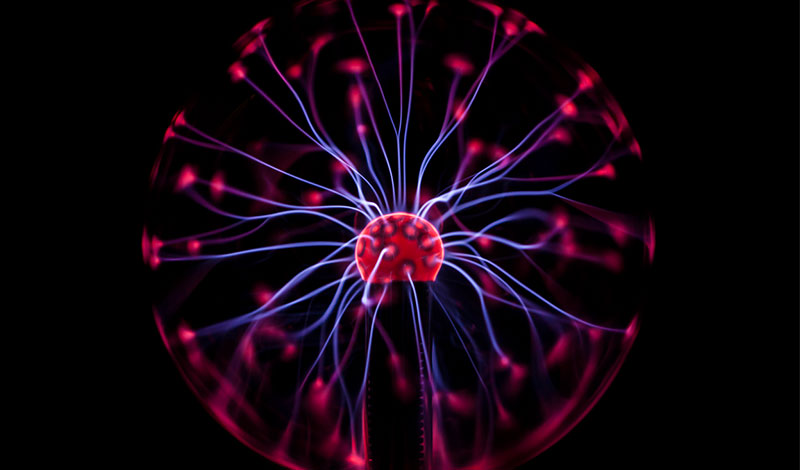

Plasma is the 4th state of matter after solid, liquid, and gas. Plasma contains a significant portion of charged particles, both ions and electrons. The presence of these charged particles makes plasma distinct from the other fundamental states of matter.

Plasma is utilized in the development of next generation semiconductor and nano-technology devices. These devices have very demanding thin film deposition and etch requirements that necessitate controlling the ion energy and ion current density.

With traditional plasma and ion sources, for any power level, a defined level of ion current density and ion energy is generated. Denton Vacuum’s patented and proprietary technologies improves this process by controlling levels of ion energy and ion current density separately from the power level set on the plasma or ion source power supply. This enables the design of novel films with a wide range of physical, mechanical, and compositional properties. Ultimately, this means more control of stress, composition, temperature, contamination, and alloying in thin film applications.

Denton is able to do this in a number of different ways depending on the deposition or etch technology. For Plasma Ion Beam CVD, the plasma is biased to control ion energy. At the same time, a self neutralizing plasma is generated. This eliminates the need for a separate neutralizer which create other issues. For example, filament neutralizers can contaminate your film and need to be changed frequently, and hollow cathode neutralizers are expensive and hard to maintain.

For magnetron sputtering, Denton uses unbalanced magnetic fields to produce a significant negative self bias on the substrate. The self bias and high ion density result in a low energy ion flux found in other ion enhanced deposition systems, but without the need for a separate ion source. Coupled with the cylindrical magnetron shape, this enables high quality, highly uniform thin films on curved surfaces.

For Ion beam deposition, Denton biases the target to 1) control the energy levels of ions bombarding the target, 2) eliminate bombarding shields and other parts of the ion beam system which creates contamination, and 3) increase deposition rate over traditional ion beam deposition. For ion beam etch, Denton biases the substrate to control the level of energy hitting the substrate, this is particularly important for low damage etch of advanced devices under 7nm.

Denton has the technology to provide engineers with the widest process window possible to meet the needs of next generation thin film requirements, from following Moore’s Law for electronic chips to producing the best optical properties for photonic chips. Denton also enables producing optically transparent diamond-like nanocomposites used in a wide array of applications including advanced displays, lightweight plastic windows, and encapsulation of flexible films.

Plasma matters. Plasma bias adds the control you need.