Infinity

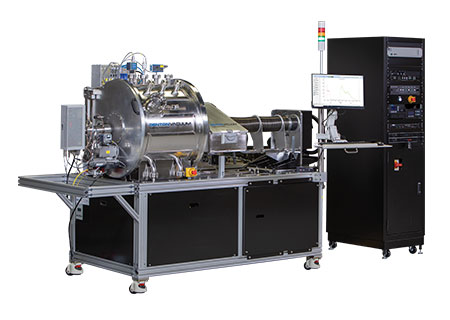

When you need a high-quality film for demanding applications such as optical interference coatings or x-ray mirror optics, the Infinity Ion Beam Deposition System is the solution for you.

View DetailsExtreme UV light (EUV) has wavelengths between 5 and 50 nm, which are much shorter than ultraviolet wavelengths. EUV lithography is required for semiconductor line widths less than 9nm.

One primary application of EUV light applications is pattern etching in semiconductor production. It is particularly important for production of next-generation semiconductors. As feature sizes get smaller and smaller, EUV’s very short wavelengths are needed to meet requirements for 7nm semiconductor processing. Due to the small feature size, extremely low particle counts on the mask blanks are necessary.

An EUV mask blank is a key component used in EUV lithography. The goal is to make defect-free EUV mask blanks and photomasks, because if the blank or mask has a defect, the irregularities might get printed on the wafer. Ion Beam Deposition using Denton’s patented bias target technology eliminates contamination and defects common in magnetron sputtering and traditional Ion Beam Deposition.

When you need a high-quality film for demanding applications such as optical interference coatings or x-ray mirror optics, the Infinity Ion Beam Deposition System is the solution for you.

View Details