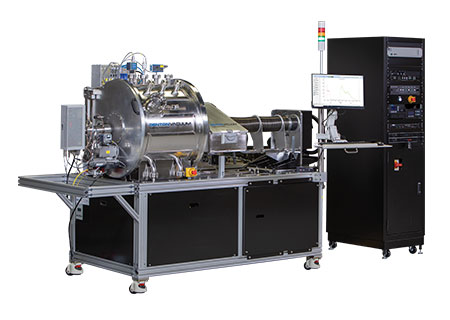

Infinity Ion Beam Deposition

The Infinity IBD System delivers dense, defect-free films with extremely high precision and thickness uniformity. It offers independent control over ion energies, so you can achieve exacting thin film specs with very low contamination from flaking.

View Details