Voyager

The Voyager is a plasma-enhanced chemical vapor deposition (PE-CVD) system that excels by providing best-in-class flexibility, process control, and sputtering options.

View DetailsDiamond-like nanocomposites (DLN) are hard clear films that enhance the durability of displays and other applications where optical transparency is required. The low-friction and low-wear DLN coatings, combined with low internal stress and good adhesion, make this type of coatings an excellent candidate for many tribological applications in the automotive, semiconductor, display, and opto-electronics industries as well as anti-reflective coating applications such as eyeglasses and solar panels. Denton’s PIB-CVD uniquely enables deposition on uncoated plastic substrates.

DLN coatings are usually deposited using a PE-CVD (plasma-enhanced chemical vapor deposition) process. The advantages of PE-CVD are high deposition rates, low substrate temperatures, and highly conformal coatings. The tunable Plasma Ion Beam CVD (PIB-CVD) process used in DLN coating is used for lower temperature operation and depositing hard films on uncoating plastic substrates.

The Voyager is a plasma-enhanced chemical vapor deposition (PE-CVD) system that excels by providing best-in-class flexibility, process control, and sputtering options.

View Details

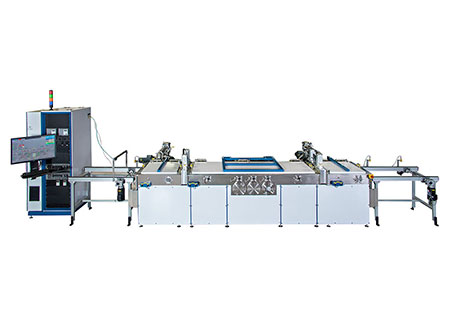

The Phoenix Magnetron Sputtering system offers high throughput for large volume production, and supports both planar and 3D component processing. This system can accommodate PIB-CVD as well as RF, DC and pulsed DC sputtering processes.

View Details