Voyager

The Voyager is a plasma-enhanced chemical vapor deposition (PE-CVD) system that excels by providing best-in-class flexibility, process control, and sputtering options.

View DetailsDLC, or diamond-like carbon, coatings are thin films that are deposited on other materials in order to provide many of the beneficial wear resistant properties commonly associated with diamonds, such as hardness, chemical and scratch resistance, and lubricity, which minimizes friction.

DLC coatings can be used in a range of applications including protective coatings for sensors and flexible semiconductors, where they greatly increase durability and can extend the total life of the final product.

DLC coatings are often deposited using a PE-CVD (plasma-enhanced chemical vapor deposition) process. The advantages of PE-CVD are high deposition rates, low substrate temperatures, and highly conformal coatings. Materials with low melting temperatures such as polymers can be deposited with DLC coatings to improve their surface hardness.

Denton Vacuum has developed several unique thin film deposition equipment configurations. One example is a DLC coating system with the capability of sputtering metal films to deposit metal-doped DLC (Me-DLC) films. The properties of Me-DLC films can be tailored to meet the hardness, electrical resistivity, and wear resistance needs of unique product applications, such as in microelectromechanical systems (MEMS) sensors.

The Voyager is a plasma-enhanced chemical vapor deposition (PE-CVD) system that excels by providing best-in-class flexibility, process control, and sputtering options.

View Details

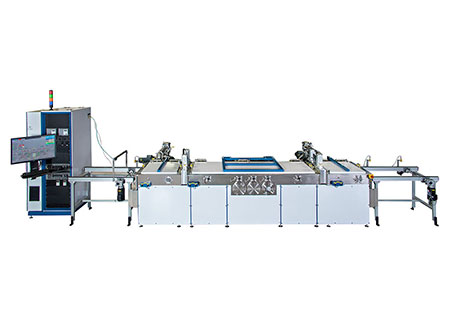

The Phoenix Magnetron Sputtering system offers high throughput for large volume production, and supports both planar and 3D component processing. This system can accommodate PIB-CVD as well as RF, DC and pulsed DC sputtering processes.

View Details