Posted on

The bi-annual LASER World of PHOTONICS show is coming up at the end of the month in Munich, Germany, and there are sure to be plenty of new technologies and emerging applications on display, as well as further developments for mature applications. Here are some of the trends you can expect to hear more about at the show.

Trends and Applications to Look For

Machine vision: Machine vision technology is used primarily in industrial automation and is used to extract data from an image for the purpose of analysis and feedback. Machine vision is very often used in automatic inspection, identifying the orientation and position of objects in a frame. It can be used to give process guidance and feedback, as well as for security monitoring, and better enables automation in factory settings. As AI and IoT become more integrated in industrial settings, applications and demand for machine vision will continue to grow.

Biophotonics: Lasers are used in medical applications to treat or remove tissues by emitting a very narrow wavelength of light. Currently, medical lasers are used in cosmetic surgery, refractive eye surgery, dental procedures and general surgical procedures, but there are several emerging applications for these devices, including photonic diagnostics. Through laser technology, medical professionals can use non-invasive techniques such as laser radiation to examine human tissue and capture info on medical conditions and progression. There is also potential for medical lasers to be used to destroy tumors without requiring a surgical procedure.

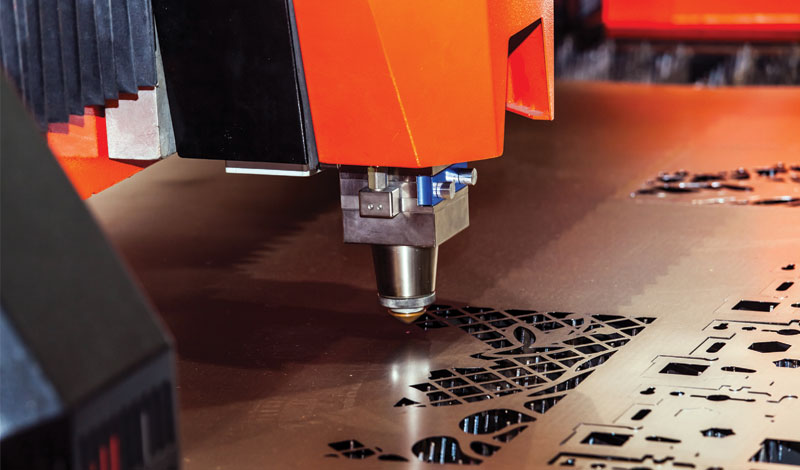

Materials processing: In our blog post earlier this year on the state of the laser market, we noted that high-power fiber lasers for metal-cutting are expected to lead the growth in demand for industrial lasers. Lasers offer one of the most efficient and precise means of production, and are already being used in manufacturing for the aerospace and automotive markets. Currently, sophisticated laser systems are needed to meet exacting specifications and ensure performance, and as these systems become more automated, they’ll become a top manufacturing method for many other markets.

Thin Film Needs for Laser Applications

Precision and quality performance are required for laser devices both in the applications listed above and future applications that will drive demand. Achieving this requires a highly repeatable and reliable thin film deposition process that very precisely hits specifications. Repeatability and precision ensure performance, allowing laser manufacturers to take advantage of growth in each sector.

Compatibility with ion sources and in-situ controls is also key for your laser coating system. If your system is fully integrated with an optical monitoring system, you’ll get real-time control over the thin film deposition process, improving precision and yield. Pairing your system with an ion source for ion assisted deposition provides better adhesion, along with moisture stability and index of refraction of the laser coating.

Denton Vacuum will be on hand at the upcoming LASER World of PHOTONICS show in Munich, and we’ll be showcasing the Integrity, our proprietary laser facet coating solution. The Integrity ensures excellent control over thin film stability, adhesion, density and optical properties for multilayer optical interference coatings in laser diode production. Check out the Integrity brochure or visit Denton in Hall B1, Booth 631, from June 24-27.