Posted on

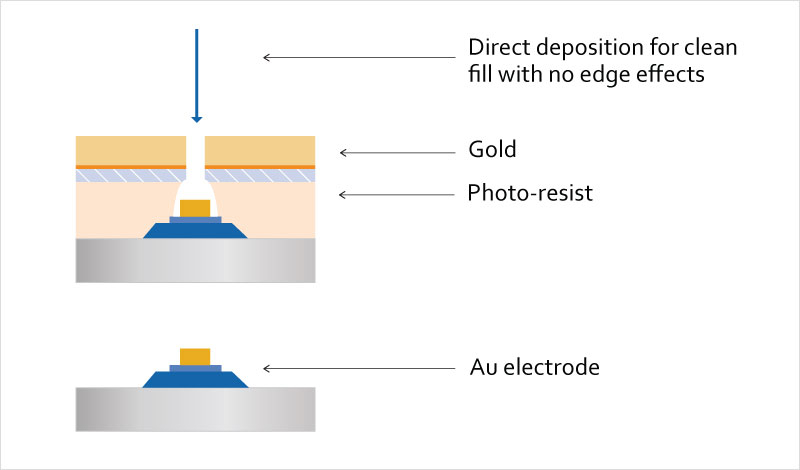

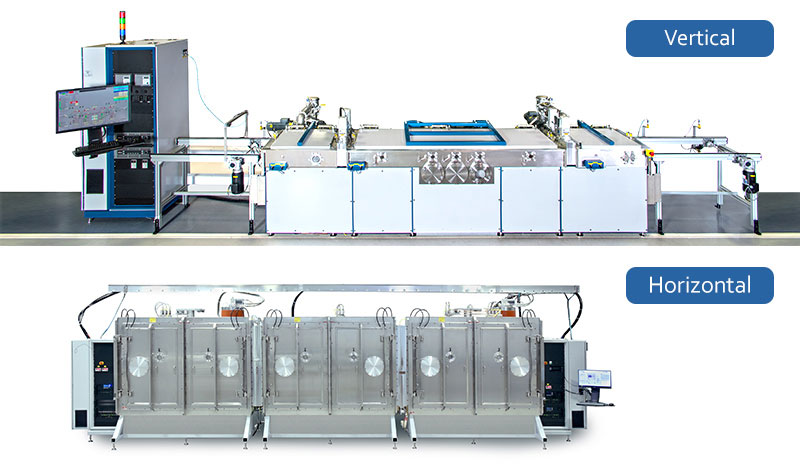

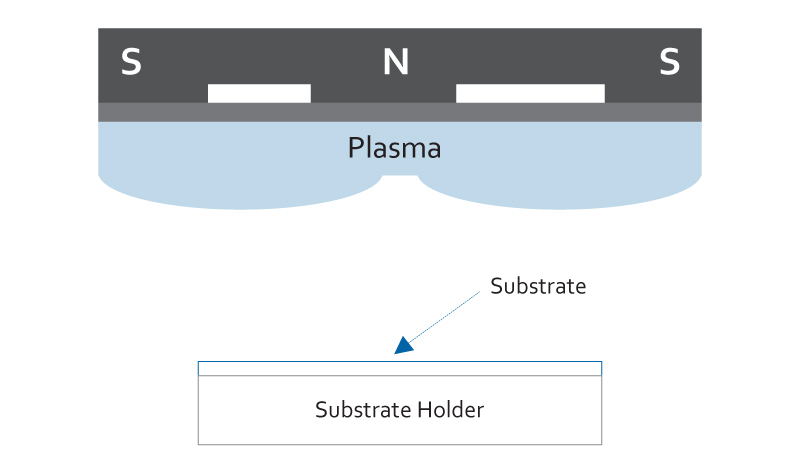

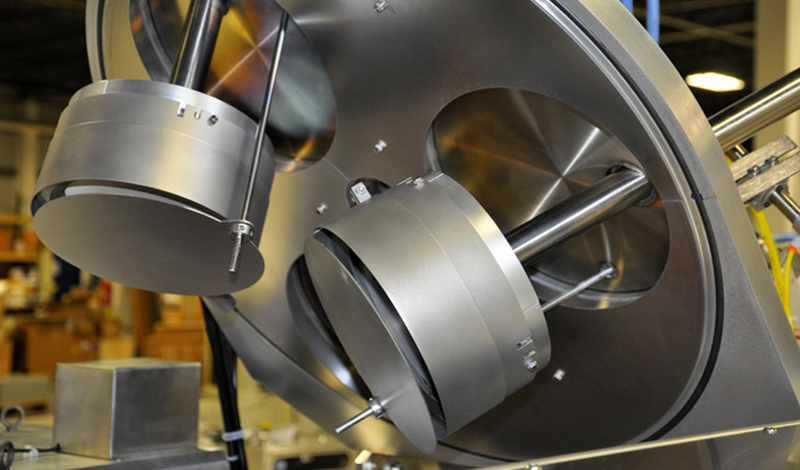

Enabling Sputtering from the Target Only Bias Target Sputtering (BTS) has excellent process control and stoichiometry while reducing contamination and lowering cost of ownership. The ultralow contamination leads to higher performance in lasers and fewer defects enables higher laser damage threshold. BTS is also used for EUV mask blanks which must be defect-free or the… Read More