Posted on

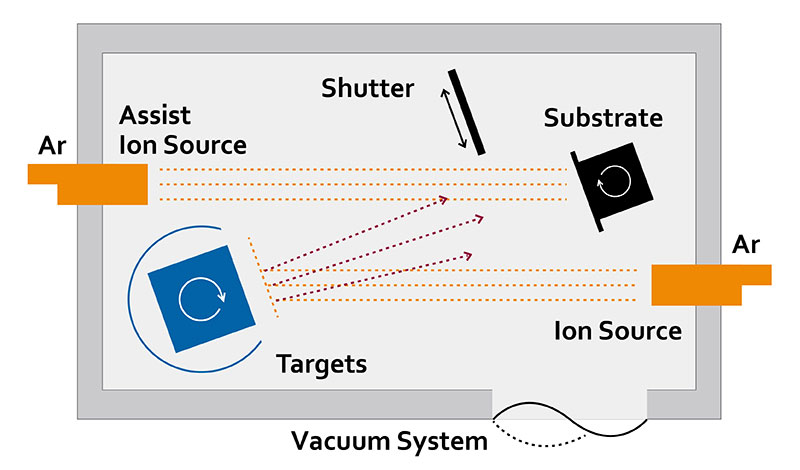

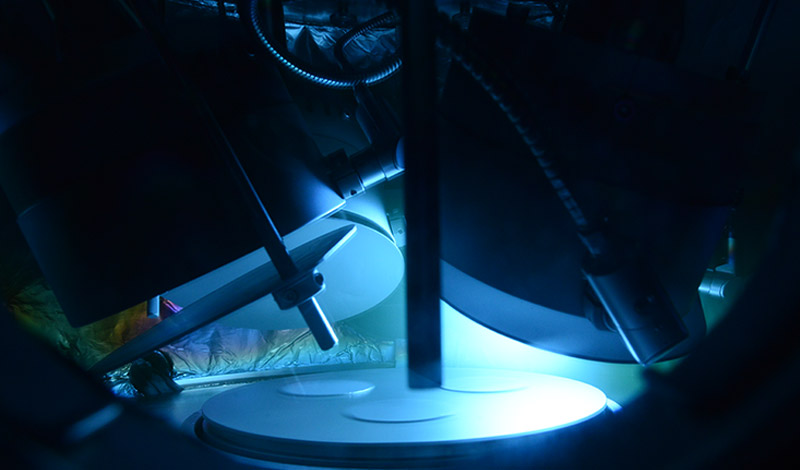

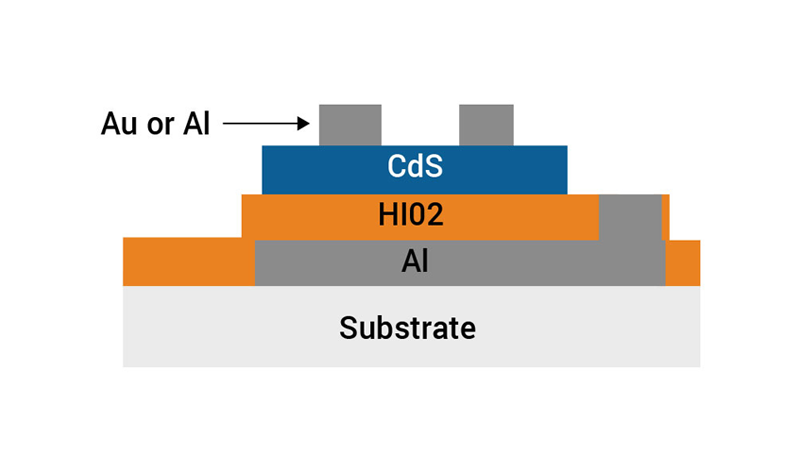

Ion beam deposition (IBD) is a thin film deposition method that produces the highest quality films with excellent precision. Also referred to as ion beam sputtering (IBS), it’s a process that’s used when tight control over film thickness and stoichiometry is needed. How it Works During the ion beam deposition process, an ion source is… Read More