Posted on

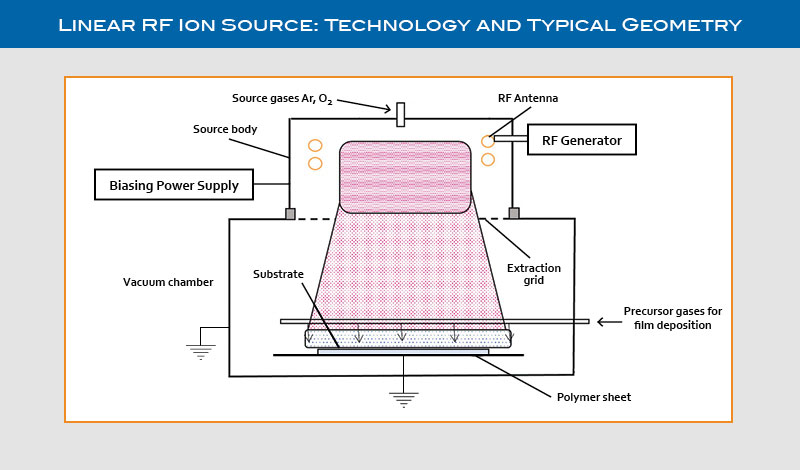

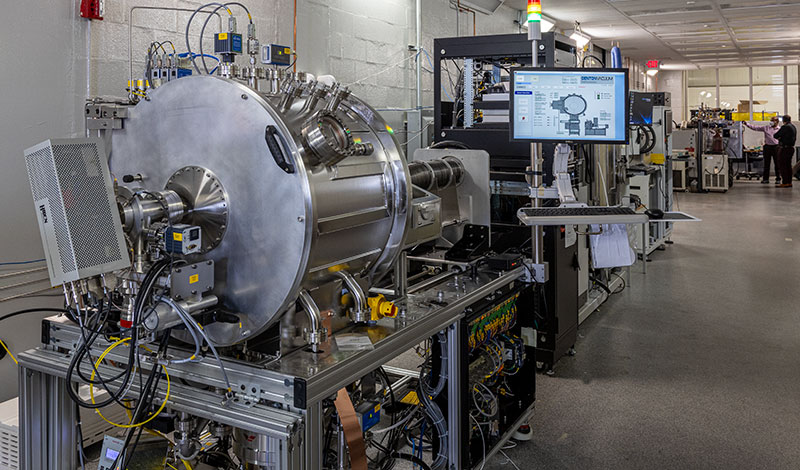

Thin films obtained by standard chemical vapor deposition (CVD) typically require temperatures ranging from 600°C to 800°C. Using plasma enhanced CVD (PE-CVD) allows reactions to occur at temperatures down to 350°C. Plasma ion beam CVD (PIB-CVD) advances this process even further by allowing room temperature deposition. Without the need to heat a substrate to such… Read More