Posted on

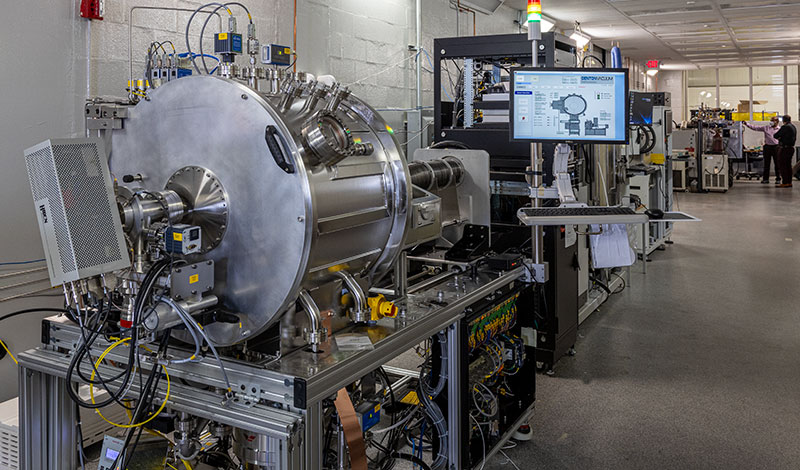

Inspired by his work at the Frankford Arsenal in Philadelphia during World War II, Peter Denton established Denton Vacuum with the purpose of being an innovator in thin film deposition technology. Today, Denton is proud to offer state of the art deposition and etch solutions that utilize our proprietary technology. In this video, see the… Read More