Posted on

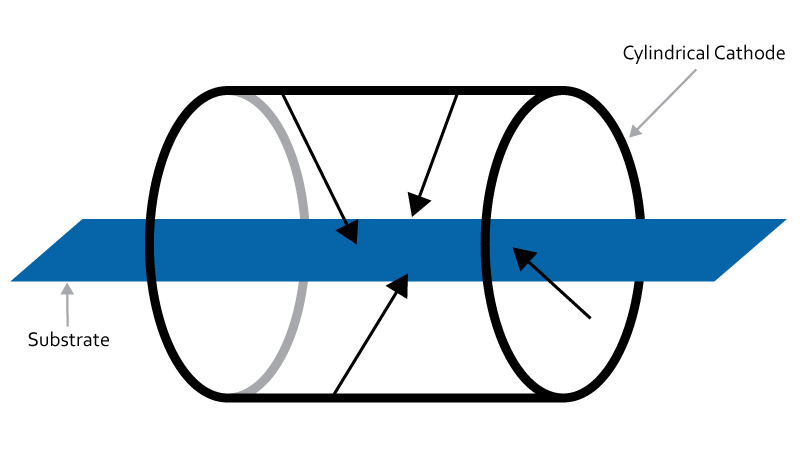

In order to achieve the desired properties and meet performance requirements, substrates may need to be pre-cleaned prior to deposition. While there are several methods that can be used to carry out this process, each has its own benefits depending on your pre-cleaning goal and deposition process. For example, RF glow plates use lower energy… Read More