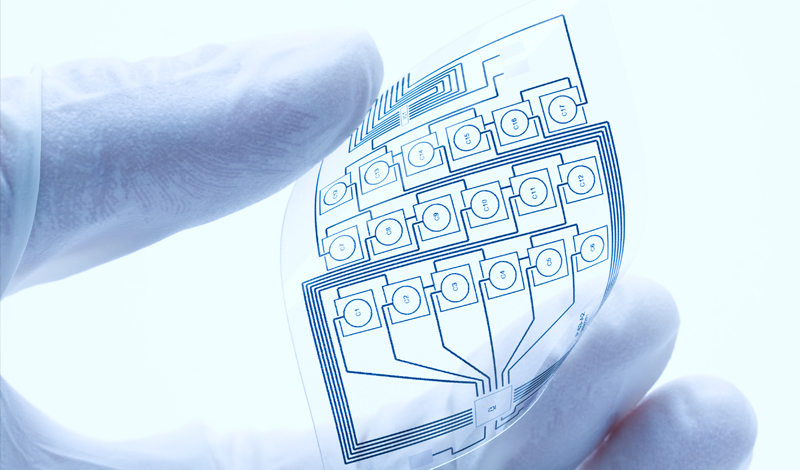

Thin Film Components of RF Filters

Posted on

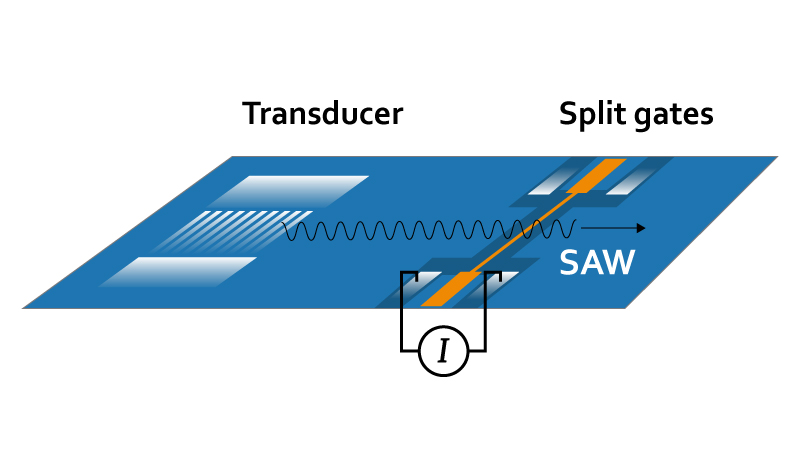

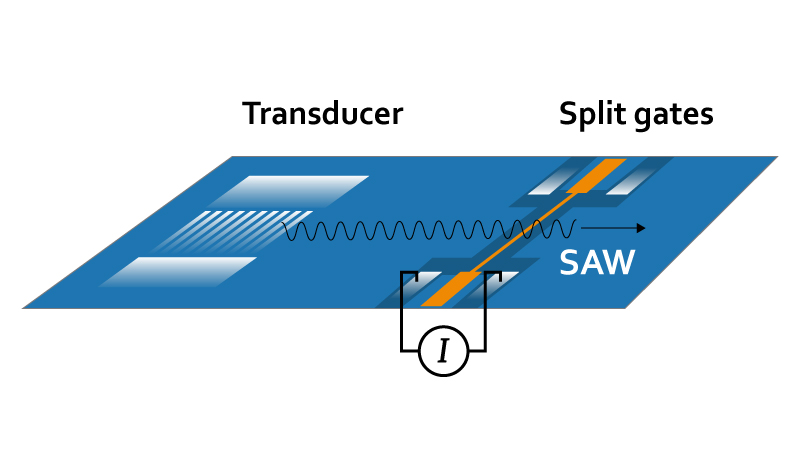

There are two types of acoustic wave components that play a role in RF filter technologies: surface acoustic wave (SAW) and BAW (bulk acoustic wave). They are both important devices for filtering and amplifying RF signals in many applications using wireless communication, and a repeatable, high-vacuum thin film coating process is needed to ensure good… Read More