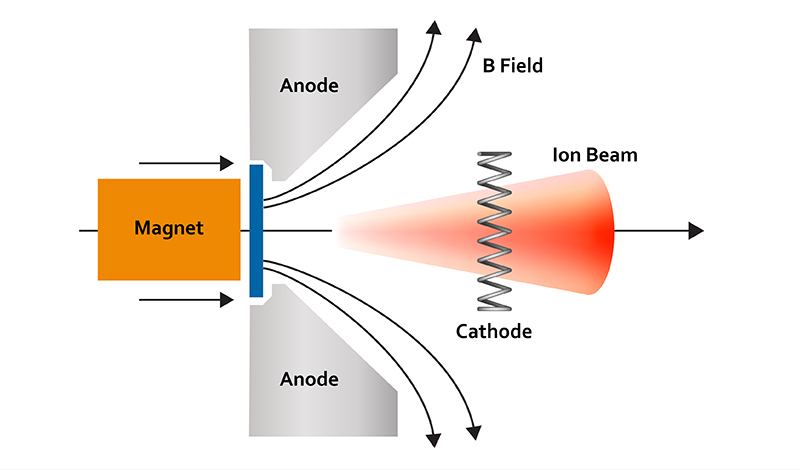

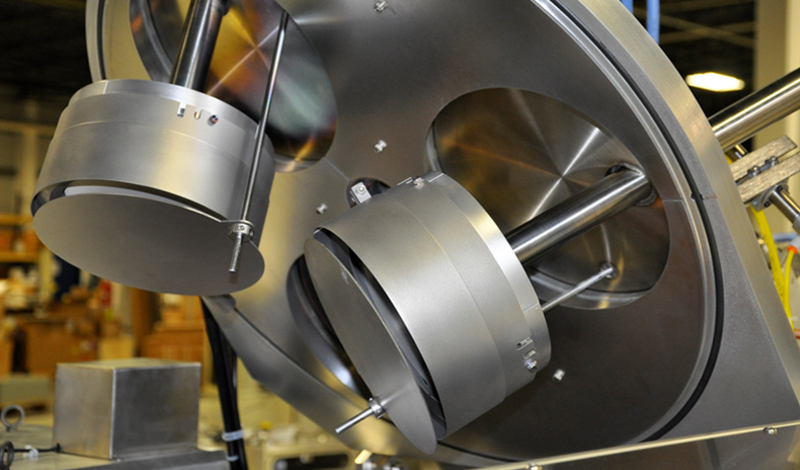

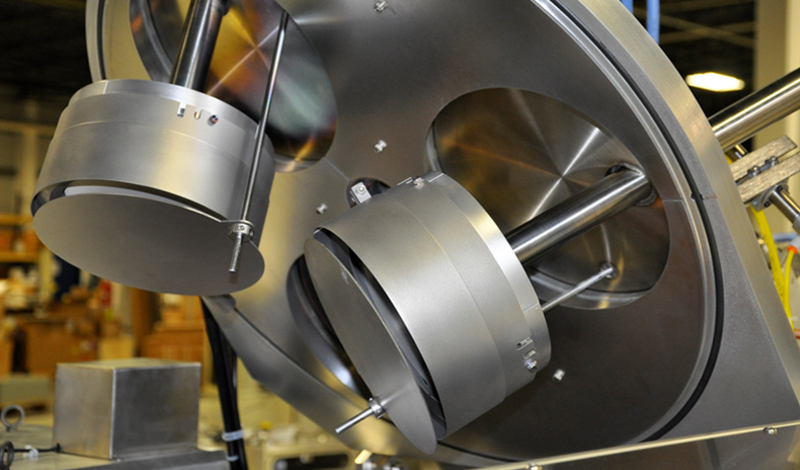

Benefits of Confocal Cathode Placement During Sputtering

Posted on

During sputtering, there are several different approaches for cathode placement, depending on what you need to achieve from your process. Positioning the cathodes confocally to the substrate is the preferred method for co-sputtering multiple materials during deposition. Cathode Placement Approaches Where the cathode or cathodes are placed in relation to the substrate can have an… Read More