Improving Yield and Throughput in III-V Semiconductor Manufacturing

Posted on

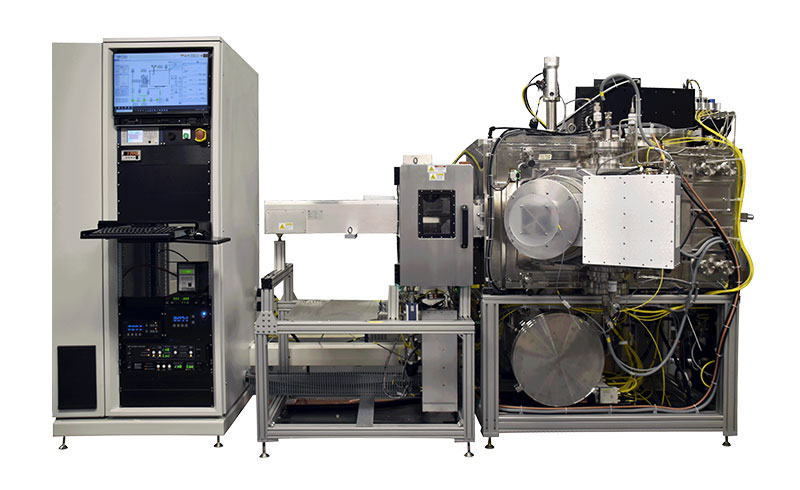

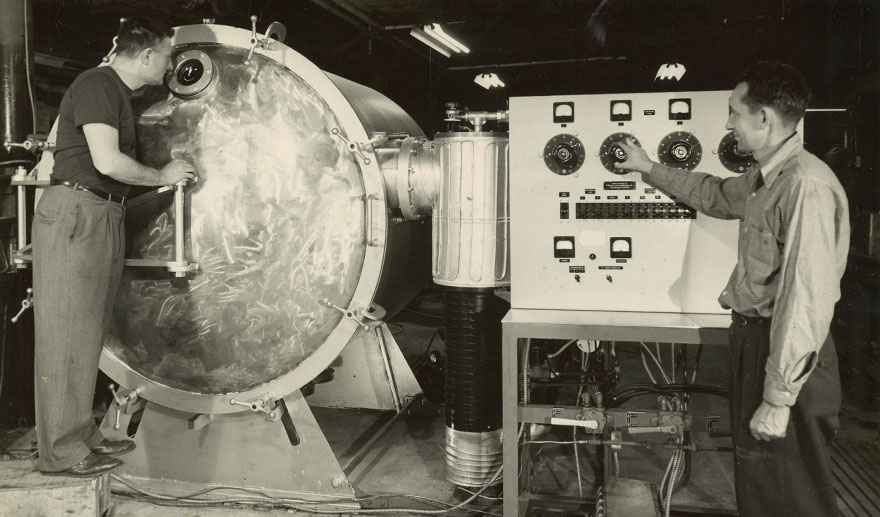

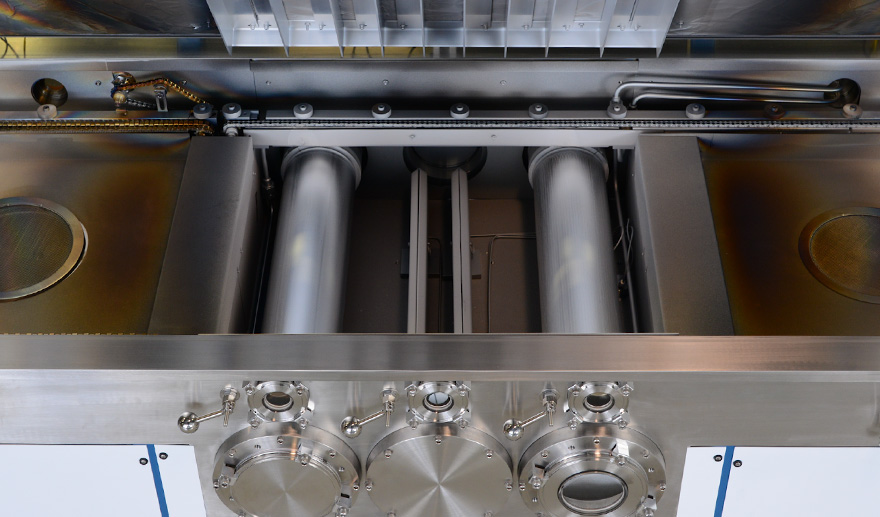

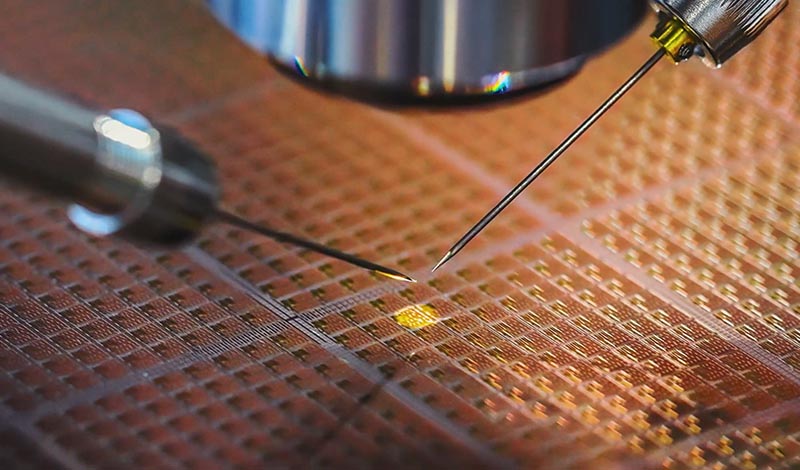

Many of today’s electronic devices are based not on silicon semiconductors – the mainstay of the computer industry for decades – but on III-V semiconductors, built using specialized alloys with unique properties. However, the inherent cost, brittle nature, and unique characteristics of III-V semiconductors often demand special material handling during the manufacturing process. Denton offers… Read More