Posted on

Oxide thin film coatings have a number of different uses, including optical and semiconductor applications. For these thin films, hitting the right specs is absolutely critical to performance. When those specs are reached with the right thin film deposition process, oxide films provide a variety of benefits.

Benefits and Uses for Oxide Films

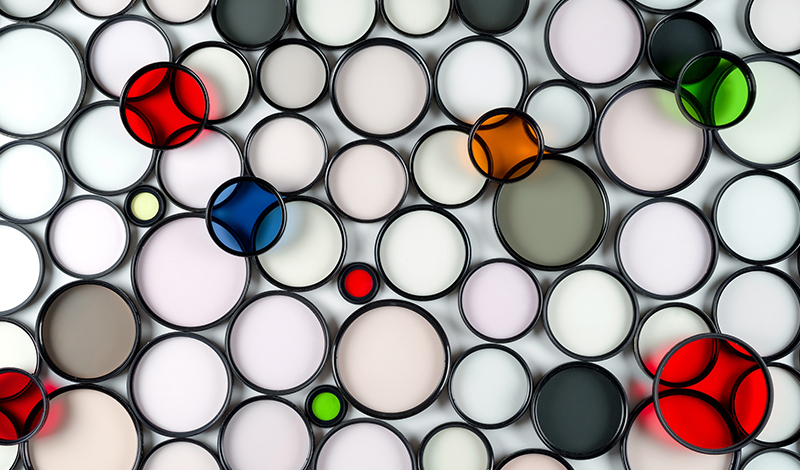

In optics, oxide films are primarily used in optical filters and coatings. Each oxide material has a certain refractive index which, when combined with other oxide materials, can be used to modify light transmission properties. By selecting the right combination of materials for your thin film coating, you can create high reflectivity to produce mirrors, cut down on glare in virtual reality headsets, or filter out visible light in a smartphone face recognition application.

Oxide films are also used as barrier layers and thin film resistors in compound semiconductors. In these applications, they provide control over the electrical current characteristics to allow for current confinement or the fine tuning of resistance.

Deposition Methods for Oxide Films

Common types of thin films are silicon oxide, aluminum oxide, and titanium oxide. These films require good thickness uniformity and repeatability, particularly for optical applications with tight bandwidth requirements, such as notch filters. Any deviation from the target will shift the notch of an optical filters, which would provide the wrong transmission characteristics. Repeatability from run to run ensures that each spec will be hit and that the film will function properly unit after unit.

Ion assisted e-beam evaporation, magnetron sputtering and ion beam sputtering are the most common deposition methods for oxide films and optical coatings. All options offer good uniformity, with ion assisted e-beam evaporation presenting a more cost-effective solution. Magnetron sputtering is also a good option if easy scalability or automation are process requirements. Ion beam sputtering is used when the highest density films are required.

To fully address process needs and produce high-quality optical coatings, a complete precision optics deposition system is needed. With precision designed into an e-beam evaporation system and in-situ controls added on, the platform will offer tight control over reflectance, transmittance, absorbance, and resistance. Adding a plasma emission monitor (PEM) works well for providing real-time feedback and adjustments during deposition for maximum repeatability and composition control.

Plasma emission monitoring is also excellent for increasing deposition rates while lowering total cost of ownership. To learn more about how a PEM can improve oxide film deposition, read our white paper, “Tantalum Oxide Transition Mode Reactive Sputtering by Plasma Emission Monitor Control.”