Posted on

In order to achieve the desired properties and meet performance requirements, substrates may need to be pre-cleaned prior to deposition. While there are several methods that can be used to carry out this process, each has its own benefits depending on your pre-cleaning goal and deposition process. For example, RF glow plates use lower energy than other methods and are good for simple pre-cleans to remove hydrocarbons or moisture, but are not practical when entire layers need to be removed.

In this video we discuss 5 key considerations for choosing an optimal pre-cleaning method.

Video Transcript

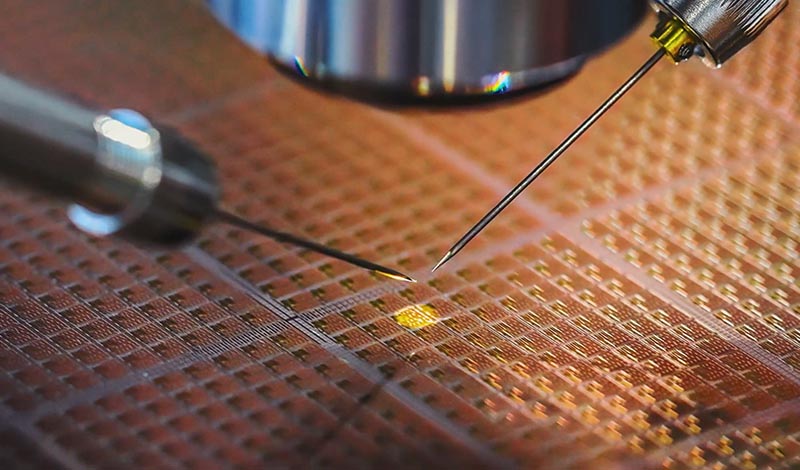

In the thin film deposition process, pre-cleaning removes unwanted contaminants from substrates before applying a thin film coating. Pre-cleaning can greatly improve adhesion to the substrate, leading to better performance and reliability for the coating.

There are Five Key Considerations in choosing an optimal pre-cleaning method.

One: The deposition method. For example, ion-source pre-cleaning technologies are directly compatible with evaporation systems but do not work well with sputtering systems.

Two: The types of contaminants being removed. For removing hydrocarbons and water molecules from the surface, a low ion energy method is sufficient. If removing entire oxide layers, an energetic ion source is necessary.

Three: Coverage area. RF glow plate and plasma pre-treater methods can cover large areas, while RF or microwave pre-treaters and circular ion sources offer more limited coverage.

Four: The sensitivity and damage threshold of the substrate material.Typically, higher-energy, higher-density methods are more susceptible to causing surface damage.

And finally, Five: The cost and complexity of the application. If an application does not require a high-energy or high-density pre-clean, then a lower energy approach will help optimize your process and lower costs. Choosing a method without considering surface sensitivity can lower yield and negate any process benefits.

Conclusion

To learn more, download our technical paper Pre-Cleaning in Thin Film Physical Vapor Deposition where we discuss the different methods available and their benefits, factors to consider before choosing a method, and application-specific examples.