Posted on

Precision optics applications require thin film coatings to meet very exacting specs for factors such as refractive index, optical loss, thickness, optical transmission and uniformity. To do this, manufacturers need a full precision optics coating system configured with in-situ control that directly monitors optical properties.

Effects on Performance and Yield

In precision optics, the acceptable margin for error when it comes to thin film is very small. Meeting the desired specs is particularly important for filters because it can significantly impact performance. For example, laser safety goggles are designed to block a particular wavelength while passing others (a “notch” filter). If the thicknesses are too far out of spec, the blocked wavelength will miss the laser light, allowing it to pass through and causing very serious eye damage for the end user.

But because these filters have such tight specs, it’s difficult to have high yield. This is obviously a concern for high-throughput applications but it can have a major impact on cost of ownership even for smaller runs and lower-throughput production. To cut down on cost of ownership for your entire system, it’s recommended to configure the system with an optical monitor that can assess critical properties in real time.

Benefits of Monitoring Optical Thickness

Thickness is one of the most important properties for ensuring accuracy and performance. There are two ways of monitoring thickness during the optical coating process:

- Physical thickness, which refers to the actual thickness of the coating itself

- Optical thickness, which refers to coating thickness in terms of light wavelength; this is physical thickness times the refractive index for the particular wavelength of interest

An in-situ optical monitoring system (OMS) is a great option for monitoring optical thickness as the coating is being deposited. An OMS can ensure that the optic meets the exact specs needed for performance requirements.

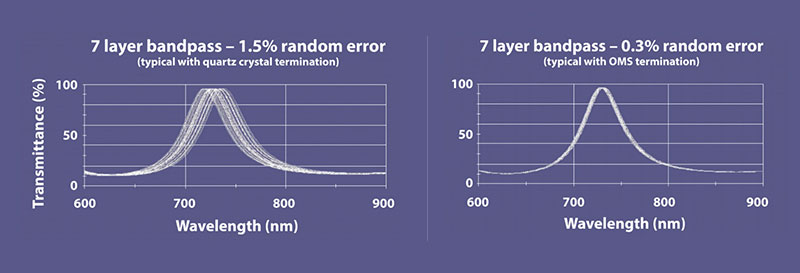

A few of the benefits of using an OMS, compared to a method like quartz crystal monitoring (QCM):

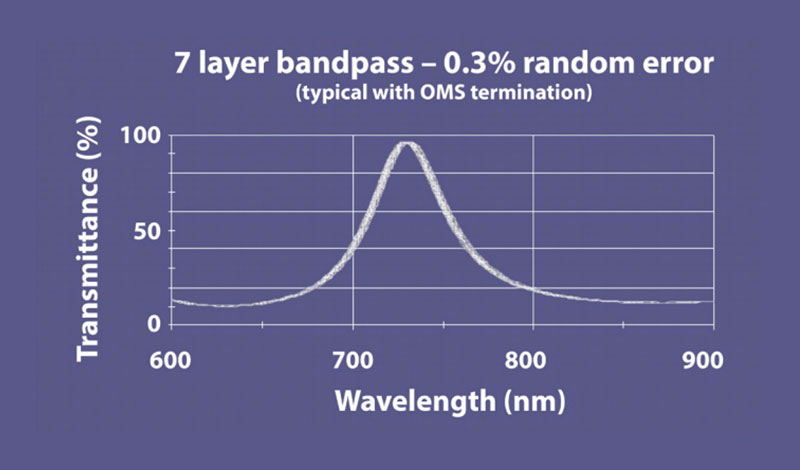

- Excellent precision: The number one benefit is the ability to build in high precision for optical properties into your configuration. This is especially important for multilayer optical stacks, where it can be a challenge to measure factors such as optical transmission just by monitoring the physical thickness and properties of the thin film.

- Real-time control: An OMS gives you control over your optical coatings while thin film deposition is going on. With accurate feedback during deposition, you can make the necessary adjustments to hit thin film specs right away, as long as your system and OMS are integrated with a robust software package.

- Increased yield: Both the high precision and the ability to adjust coatings in real time will raise the overall yield for your system. You’ll be able to create more usable optics that fall within the very tight but necessary specs to ensure performance, on the same deposition system.

Factors for Consideration

When it comes to an optical monitoring during thin film deposition, there are two main methods used: direct and indirect.

- Direct monitoring monitors the actual substrate in real time as it goes through the coating process.

- Indirect monitoring monitors a separate chip that is also coated within the same deposition chamber.

Both direct and indirect monitoring have benefits and drawbacks when it comes to ensuring very specific optical properties for performance. And there are other approaches and factors that need to be weighed, such as:

- Single wavelength vs. broadband

- Transmission vs. reflection

To read more about how an OMS can help improve yield and optical thickness control for multilayer stacks, download Denton Vacuum’s use case.